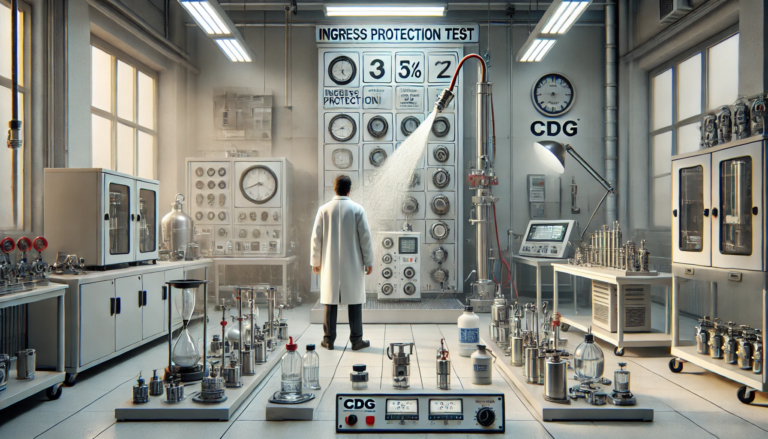

In a world where electronic devices are an integral part of our daily lives, ensuring their durability and longevity is paramount. One critical aspect of this durability is ingress protection (IP) testing, which determines how well a device is shielded from dust and moisture. Today, we’ll delve into the specifics of how IP2X is tested for dust protection, unraveling the process and its significance in safeguarding your electronics.

Introduction: Why IP Testing Matters

Imagine a dusty workshop where precision tools are used daily. In such environments, even a small amount of dust can wreak havoc on sensitive electronics. This is where IP testing comes into play. The IP rating system, developed by the International Electrotechnical Commission (IEC), provides a standardized method to evaluate how effectively a device is protected against the intrusion of foreign objects and moisture.

Among the various IP ratings, IP2X focuses on dust protection, specifically addressing how well a device withstands the ingress of dust particles. Understanding and testing IP2X can make the difference between a device that performs reliably in a harsh environment and one that fails prematurely.

The IP2X Rating Explained

The IP2X rating is part of the broader IP (Ingress Protection) code, which uses two digits to indicate the level of protection against solids and liquids, respectively. In the case of IP2X:

The first digit (2) refers to protection against solid objects, including dust.

The second digit (X) represents protection against liquids, but since we’re focusing on dust, this digit is not relevant for IP2X.

Specifically, the IP2X rating means that the device is protected against the ingress of objects larger than 12.5 millimeters in diameter, such as fingers or tools. However, it does not guarantee complete dust-tightness.

Testing IP2X for Dust Protection

Testing a device for IP2X involves a meticulous process to simulate real-world conditions. Here’s a step-by-step guide on how this testing is typically conducted:

Preparation: The device is first examined to ensure it is in a typical operating condition. All ports, covers, and seams are inspected for potential vulnerabilities.

Dust Chamber Setup: The device is placed inside a dust chamber. This chamber is filled with fine dust particles, often composed of a material like talcum powder or silicon dioxide, which mimics the dust found in real-world environments.

Exposure: The device is exposed to the dust for a specified duration, usually several hours. The dust chamber’s design ensures that the dust is evenly distributed and that the device is subject to a consistent dust load.

Inspection: After the exposure period, the device is carefully removed and inspected. The key areas of interest are any openings or seams where dust might have infiltrated. The inspection focuses on both the external and internal parts of the device to ensure no dust has compromised its functionality.

Evaluation: The results are evaluated to determine if the device meets the IP2X standard. If the device shows any signs of internal dust ingress that could affect its performance, it does not pass the test.

Practical Tips and Real-World Applications

For manufacturers and consumers alike, understanding and applying IP2X standards can enhance the reliability of electronic devices in dusty environments. Here are a few practical tips:

For Manufacturers: Incorporate robust sealing solutions and design features that minimize dust ingress. Regularly test prototypes to ensure they meet IP2X standards before production.

For Consumers: When purchasing electronics for use in dusty environments, check the IP rating to ensure it meets the necessary standards. Devices with higher IP ratings offer better protection and are a wise investment for harsh conditions.

Incorporating IP2X testing into the design and evaluation of electronic devices is essential for ensuring they can withstand dusty environments. By understanding the testing process and its significance, manufacturers can create more reliable products, and consumers can make informed choices to protect their investments.

If you’re interested in learning more about ingress protection testing or need assistance with IP testing for your devices, contact CDG today. Our experts are here to help you ensure your products meet the highest standards of durability and performance.